Overview

The robotic system, based on two KUKA palletizing robots, is designed for high-performance palletizing of alcohol product boxes.

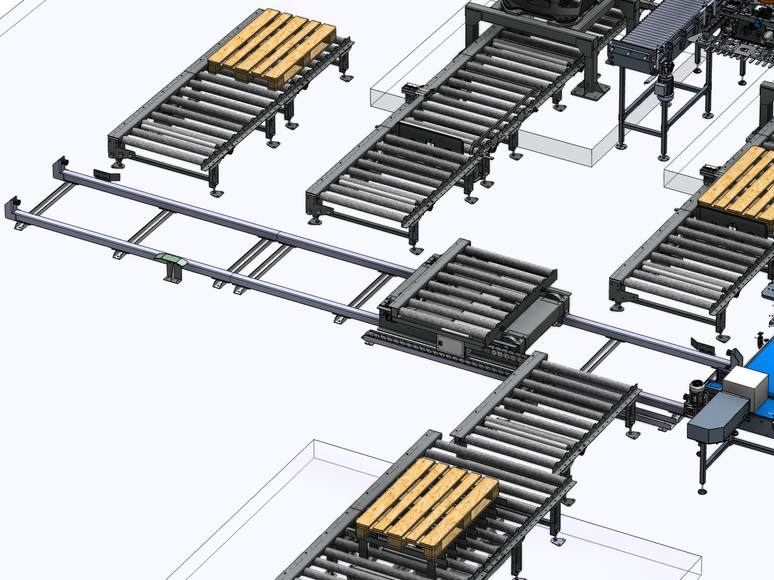

The system ensures the automated supply of empty pallets, removal of filled pallets from the palletizing area, and wrapping of filled pallets with stretch film. At the final stage, a pallet accumulation zone is provided with a capacity of up to four positions (the illustrations show one of them). Additionally, a manual palletizing zone is organized, equipped with its own transport system for feeding boxes and removing filled pallets.

The pallet transport system includes:

A dispenser for supplying empty pallets,

Shuttles (mobile roller conveyors) of two types,

Roller conveyors for pallet transportation,

Roller conveyors for place points,

A lifting device for filled pallets in the wrapping area.

The box transport system consists of:

Straight and curved modular belt conveyors,

Devices for pushing, delaying, and turning boxes,

Roller conveyors for pick points.

The system is designed to ensure reliability and efficiency, providing seamless operation in both automated and manual modes.

My Role

As a Project Engineer:

Developed the layout solution for the robotic system and determined the composition and specifications of the required equipment.

As a Design Engineer:

Fully designed conveyor systems for box feeding, empty pallet feeding, and filled pallet removal.

A universal gripper for all box sizes has been developed.

As a Production Engineer:

Supervised the manufacturing, assembly, and installation of the equipment.

Challenges and Solutions

A special shuttle with a low pallet position (290 mm above the floor) was developed for the continuous feeding of empty pallets into the stacking area. This solution enabled the use of a single pallet dispenser for two robots, reducing the equipment costs of the robotic system. Additionally, it optimized space within the constrained workshop layout, making room for a manual stacking area as requested by the customer.