Overview

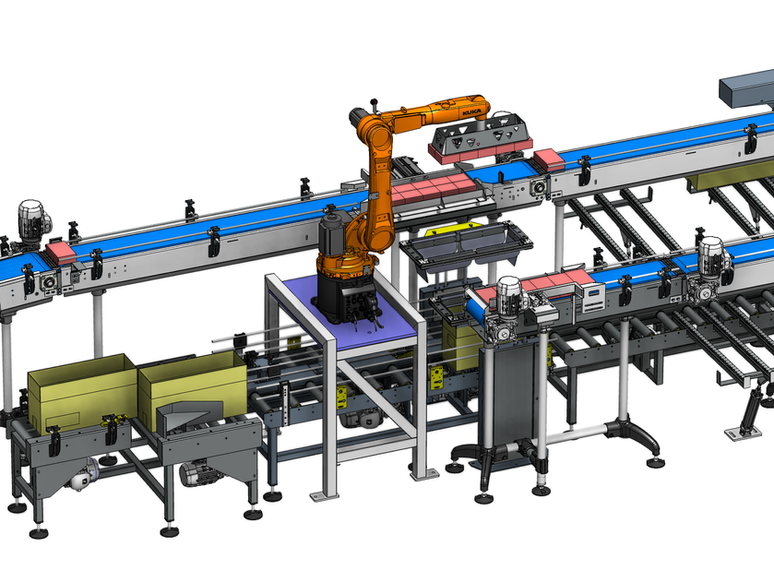

The robotic system is designed for packing sugar cube packages into cardboard boxes. The system services two production lines with different packaging sizes and cardboard box formats.

The following technological processes have been automated:

Reading barcodes on each sugar package and checking the sealing of package flaps,

Rejecting packages with unreadable barcodes or unsealed flaps,

Forming corrugated boxes and distributing them across two lines,

Packing sugar packages into boxes of 10 or 20 kg, followed by sealing the box flaps,

Printing labels with batch numbers on the cardboard boxes,

Transporting the boxes to another floor for palletizing.

My Role

As a Project Engineer:

Developed the layout and structure of the system according to client requirements.

Defined the equipment composition and technical specifications for procurement and design.

As a Design Engineer:

Designed a packaging transport system based on modular belt conveyors, including control, rejection devices, and automation components.

Designed a box transport system based on roller and belt conveyors, featuring flow separation, a pick-point with automatic adjustment for two box sizes, and manual packing stations.

Developed a vacuum gripper for sugar packages, a vacuum station with blow-off functionality, and gripping control.

As an Assembly Technician:

Fabricated specific parts using a lathe.

Assembled pneumatic and vacuum components, the pick-point unit, and contributed to conveyor system assembly.

Challenges and Solutions

The versatility and productivity of the complex allowed for the complete replacement of 18 manual workers (three shifts of 6 people) with robotic operations.

The line is designed as a continuous process: if the system stops for adjustment or maintenance, packing continues manually at designated stations.

Special attention was given to system reliability to prevent interruptions in the sugar compression process, which could lead to significant economic losses.